Hydro Canada, an industry leader since 1992, excels in crafting high-tech pipe systems. Renowned for innovation, reliability, and global export excellence, we redefine standards in quality and sustainability.

| Color | Grey/Gris |

|---|---|

| Resin | PVC |

| Specific Gravity | 0.947 +- 0.04 |

| Brookfield Viscosity | Minimum 1600 cps |

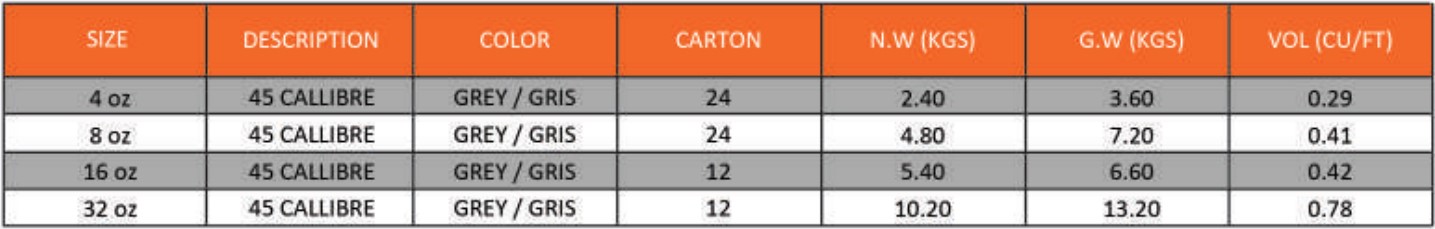

Hydro Canada 45 CALLIBRE PVC CEMENT is a grey or gris, extra heavy bodied, medium setting, high strength PVC solvent cement for all classes and schedules of pipe and fittings, including Schedule-80, with interface fit through 12-inch diameter and non-pressure Applications up to 18-inch diameter. It has good gap-filling properties and is recommended for solvent cementing joints where a sizeable gap exists between pipe and fitting e.g. large pipe sizes – and when more working time is required in warm weather.

Hydro Canada 45 CALLIBRE PVC CEMENT can be used for all types of PVC plastic pipe Applications, Type I and Type II. It is suitable for use with potable water pressure systems, irrigation, turf, conduit, industrial pipe Applications, sewer, drain, waste, and vent systems.

Detailed directions on making solvent-cemented joints are printed on the container label. An installation DVD/CD covering solvent cementing is available. It not only describes the basic principle of solvent cementing but also covers the handling, storage, and use of our products. It is highly recommended that the installer review the instructions supplied by the pipe and fitting manufacturer.

3 years in tightly sealed containers. The date code of manufacture is stamped on the bottom of the container. The stability of the product is limited by the evaporation of the solvent when the container is opened. Evaporation of solvent will cause the cement to thicken and reduce its effectiveness. Adding thinners to change viscosity is not recommended and may significantly change the properties of the cement.

Hydro Canada 45 CALLIBRE PVC CEMENT is evaluated to ensure that consistently high quality is maintained. Fourier transform infrared spectroscopy, gas chromatography, and additional in-depth testing ensure each batch is manufactured to exacting standards. A batch identification code is stamped on each can and assures traceability of all materials and processes used in manufacturing this solvent cement.